不思議なほど何も付着しない!

防汚も防食も同時に実現する

コロコートの「バイオフォウル」

海洋生物の付着はプラント運用への悪影響、腐食進行や清掃に伴う多大な労力とそこに費やされる膨大なコストロスを招きます。

海水取水口では藻類や貝類の付着が取水量を大幅に減少させることとなり、そのメンテナンスにかける時間と費用は莫大なものになります。また、付着箇所での腐食進行も避けることが出来ません。

長期間の防汚・防食を可能とする信頼できる防汚コーティングシステムは産業界に大きな利益をもたらします。

1)バイフォウル製品概要

- バイオフォウルは純銅配合三液性常温硬化型ポリエステルレジンとなります。

- 海洋・河川生物の付着防止を目的として開発されたコーティング材です。

- 無機純銅と樹脂を特殊ブレンドした製品で、純銅イオン効果により長期防汚効果を得ることが出来、それは化学物質や毒性物質よる溶出効果による防汚ではありません。

- バイオフォウルは独立した研究機関でテストされ、無毒性が確認されています。

2)バイフォウルの特徴

バイオフォウルは他の防汚コーティングと異なりハードで高耐久性であることから船体、配管、水路、取水口などの高流速域での使用に適しています。ポンプ内面への施工も可能です。

- 無毒、無公害タイプ

- 卓越した防汚効果

- 防汚効果の長期間持続性

- ハードで高耐久性

- スプレーによる短時間で容易な施工性

- 容易な再補修性

- 高耐食ベースコート施工により長期耐食性を有す

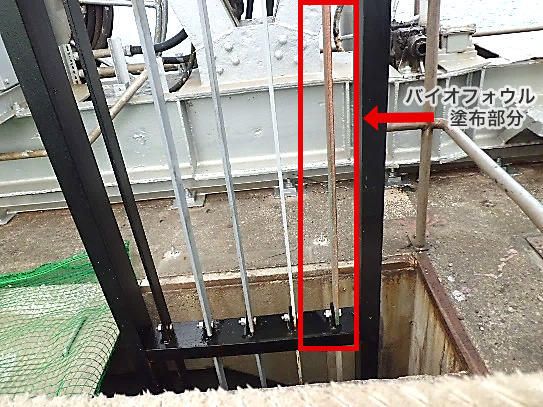

排水機場施工事例写真

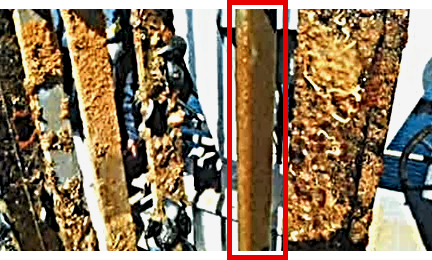

防汚コーティング性能比較試験

バイオフォウル以外にも他社製品を3種同時に同環境下でテストした事例です。

試験前の状態 右端の➡部分にバイオフォウルを塗布

施工検討時には実際の使用環境下での比較試験が行われるケースが多く、バイオフォウルもその一つとして試験に望むことも多くあります。その結果「これだけ何も付着していないよ」そう評価されるのがバイオフォウルです。

ワンポイント

防汚を目的とした塗料は多くの種類がありますが、比較実験の結果でもひと際わかりやすい結果が得られます。