Refurbish from scrap.

A complete Package for Pump Service, Repair and Protection.

- Severe corrosion/erosion damage in areas such as volutes, cutwaters, neck rings and reprofiling of water passages.

- Coating machined areas such as neck ring joints and returning coated components to original tolerances, facilitating the return of good pumping efficiency.

- Sophisticated mechanical engineering capabilities including the refurbish of impellers and the manufacture of shafts as well as metal stitching techniques.

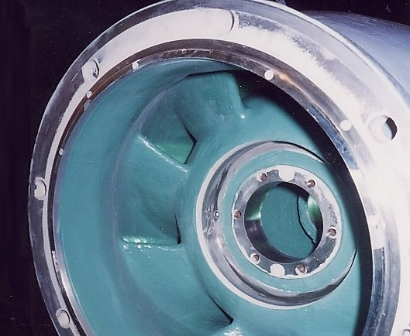

Chemical Industry: Vertical seawater pump refurbish (Φ600)

There were no manufacturer’s spare parts and the delivery time was very short to complete this project, so we had to rebuild these parts.

(Work Scope):

Refurbish of bowl Casing, Case seal, bearing, flange, guide blade and other molding

Bell suction flange refurbish and shape molding

This project was completed within 2 weeks.

Steel Industry: Refurbish and lifespan extension of 2-stage pump.

Before coating

Molding process: Welding

Reinforcement treatment: Thermal spraying

Coating application

〔 Work scope 〕

Repair and refurbish: Welding repair and machining damaged parts.

Sealing treatment: Plasmet T coating (improved corrosion resistance)

Life span: Surface hardness thermal spraying application.

Inspection: After repair completion, dynamic balance test.

One Point

Providing long-term performance, Corrocoat’s ability to combine mechanical engineering with advanced polymer technology allows even severely damage pumps to be refurbished at a fraction of the replacement cost, often without expensive replacement parts.