Normal maintenance does not end.

A complete commitment with the client is

Corrocoat pump maintenance.

Since its founding, Corrocoat Japan offers customers a comprehensive service covering refurbishment, remanufacture,modification, coating, and improved efficiency to many types of pumps.

The bespoke nature enables us to respond to individual requirements and our ability to provide equipment quickly and to budget are key elements in the all-around service we offer.

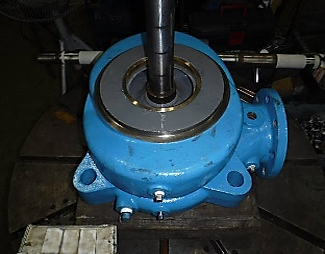

Whether it’s protective linings, reverse engineering, manufacturing spares, or offering a full turnkey solution, we are here for our customers Every pump is returned to the customer with its own completion pack, giving assurance to the client that the work has been carried out to the highest standard.

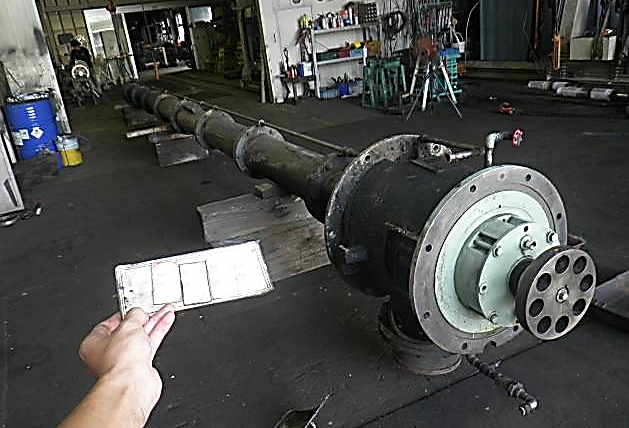

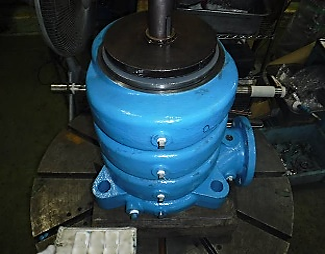

Steel Industry. Vertical scale pit pump maintenance

Before overhauling

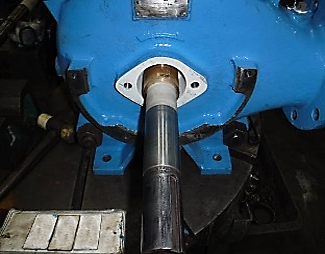

After overhauling

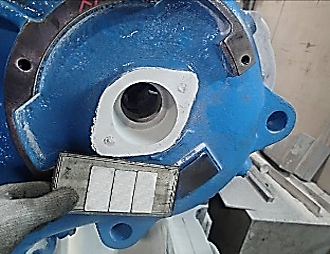

Disassembly and repair of main parts.

Parts manufacturing.

Re-engineering and repairing most damaged parts.

Assembly process

Steel Industry. Horizontal axis 4-stage pump maintenance.

Disassembling.

Parts manufacturing.

Re-engineering and repairing most damaged parts.

Refurbishment and coating

Assembling

One Point

The maintenance and refurbish of pumps implies different additional repairs.

The reasons are clear: after blasting, the defective parts and state of deterioration are identified, trying to minimize reconditioning costs, the need for parts replacement or part coating are analyzed.

In other words, we offer the best possible service at the lowest possible cost.