■ Full protection to pipe support (including steel structures).

■ Adopted as a measure that allows long-term protection.

■ Measures against salt damage on steel structures will also be implemented.

■ All of this work was done by a single contractor.

view the details

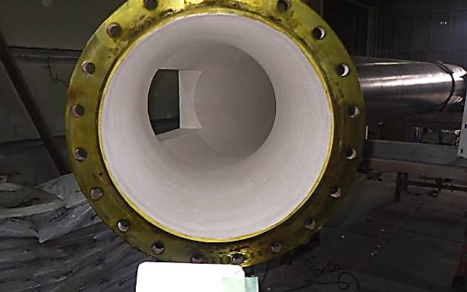

■ Adopted after the good results of the test piece in a high temperature and high corrosion environment.

■ Operating temperature of this pipe is 200°C, and since it has a chlorine gas, a coating material with excellent heat resistance and chemical resistance is required.

■ Features of Corrothane XT

・ According to product specifications, it has a heat resistance of 160℃ in a liquid environment and 260℃ in gas environment.

・ It can be used at full pH (pH 0-14).

・ It has been widely adopted as a countermeasure in high temperature and high corrosion environments.

■ Coating measures were established in a highly corroded environment.

■ Measures by coating in a highly corroded environment have become standard.

view the details

■ The use of special metals for corrosion also presents thinning of walls and holes due to the advance of corrosion.

■ Corrosion progresses throughout the plant due to exhaust gases containing filtered sulfur.

■ The Corrocoat products used in this application have shown great efficiency in saving maintenance costs.

view the details

■ Pipes that have been repaired by other companies in the past but without success opt for corrocoat products.

■ In repairs done by other companies (epoxy repairs after cleaning treatment), there is a concern of corrosion progression and recurrent failures, so a reliable product is required.

■ The basis for reliability of Corrocoat products

・ Strict surface treatment standards

・ Excellent coating performance and repair technology

・ Repair and regeneration technology for holes, defects, and thin parts

view the details

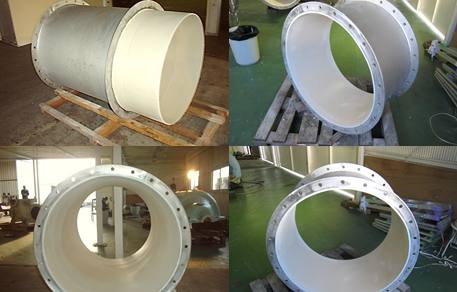

■ This product can be used in the pH range of 0-14.

■ Covers up to 110℃ in liquid and 185℃ in air.

■ Can be installed in a short time by spraying application.

■ Even with respect to expansion, contraction, and deflection, which are a concern in large tanks, the coating rate of elongation and thin-film construction provide enough flexibility.

■ Standardization of reinforcement works for tank corners and weld by fiberglass lamination treatment

■ Construction on the flange surface of the nozzle connection

view the details