| Project | Protection of concrete and outdoor equipment in saline environments |

|---|---|

| Target | Long-term corrosion-resistant protective coating |

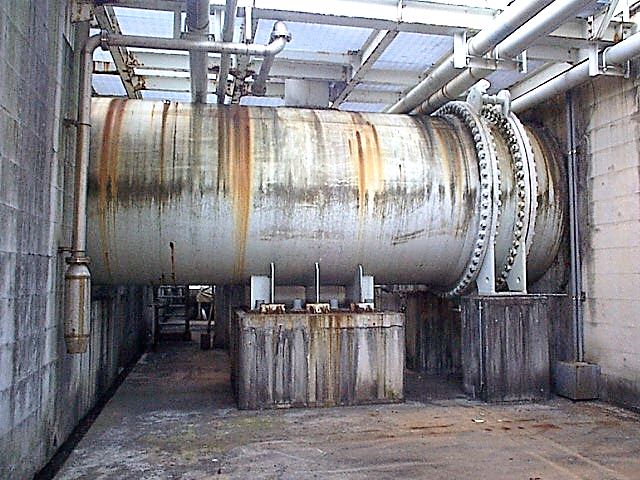

Photo description

Full view of the application area

Before application

After Plasmet ECP coating and Top coat ZE

Customers and industries

Power Industry

Target equipment

Circulating water piping

Target Item

Circulating water piping and foundation

Coating period

February 2004

Scope of work

Deteriorated concrete part of the pipe foundation.

Materials used

Plasmet ECP / ZE

(Steel parts: Plasmet ZF / ZX)

(Steel parts: Plasmet ZF / ZX)

Coating process

■ Corocoat provides with coating material

■ Surface contaminants are removed with a suitable solvent.

■ 1st layer: Plasmet ECP, 2nd layer Plasmet ZE

■ 1st layer: Plasmet ZF, 2 Layer Plasmet ZX

(Concrete)

■ Top coat is painted in the specified color

■ Surface contaminants are removed with a suitable solvent.

■ 1st layer: Plasmet ECP, 2nd layer Plasmet ZE

■ 1st layer: Plasmet ZF, 2 Layer Plasmet ZX

(Concrete)

■ Top coat is painted in the specified color

Merits of this application

■ Full protection to pipe support (including steel structures).

■ Adopted as a measure that allows long-term protection.

■ Measures against salt damage on steel structures will also be implemented.

■ All of this work was done by a single contractor.

■ Adopted as a measure that allows long-term protection.

■ Measures against salt damage on steel structures will also be implemented.

■ All of this work was done by a single contractor.

Corrocoat Japan credentials etc

■ Follow-up observations are made to confirm the merits of the application.

■ Due to the great results, in 2006, the customer decided to use Plasmet ZF/ZX to coat 2000㎡.

■ Due to the great results, in 2006, the customer decided to use Plasmet ZF/ZX to coat 2000㎡.