Engineering Excellence.

After 27 years of corrosion coating application, this pump still running in good condition.

We offer a comprehensive service for repair, refurbishment, and protection, including specialist procedures for severe corrosion/erosion damage in areas such as volutes, cutwaters, and neck rings; reprofiling of water passages; coating machined areas such as neck ring joints; returning coated components to original tolerances, facilitating the return of good pumping efficiency; sophisticated mechanical engineering capabilities including the re-manufacture of impellers and the manufacture of shafts and; metal stitching and laminating techniques.

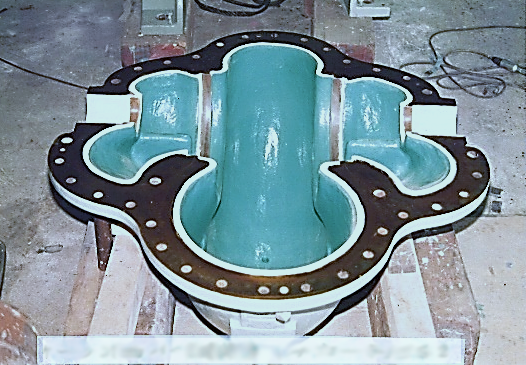

Chemical Industry: Φ600 × 600 Seawater pump (Coating repair after 27 years of Corroglas application)

1991: coating application

After 27 years application before cleaning

After cleaning

After coating repair

(Scope of work): Topcoat on slightly damaged areas (due to the effects of dust, turbulence, etc.)

Products: Corroglas 600 Series

Process of Repair & Coating: The entire surface of wet parts was completed coated and, the wear ring seat was rebuilt.

One Point

Without Corrocoat protection, it would be necessary to do major repairs such as sophisticated mechanical engineering processes.

The effectiveness of the Corrocoat methods and materials has negated the need for sophisticated methods and extended the working life of the pump.

With the Corrocoat Corrosion Engineering package, the pump lasts in excess of 27 years before any maintenance is required.