Following the early failure of the initial coating system (a European manufactured Epoxy coating), the customer was eager to find an alternative coating system that could withstand the service requirements – and additionally give extended service life without maintenance.

Corrothane XT is a cold cured vinyl ester and polyurethane hybrid developed for coating steel where high temperature resistance is required – and Corrocoat seemed the obvious choice for the high temperature sections.

Reports from the power station remain positive, and as a result of no breakdown whatsoever in the first year of operation with the Corrocoat system, Corrocoat have been awarded the refurbishment project of another similar absorber tower.

view the details

Polyglass offers a remarkably low permeation rate, combined with excellent resistance to abrasion and cathodic disbondment. The inherent durability and undercutting resistance of this high performance coating enables it to remain intact, even when damaged through to the metal substrate, with negligible under-film creep.

view the details

Plasmet T is a highly abrasion resistant coating when used on it’s own, and when coupled with glass fibre reinforcing, as in this application, builds strength and thickness to these worn sludge rollers.

Plasmet T is a machinable coating designed to achieve a smooth surface finish.

This high specification system ensures the long life of the rollers in this highly abrasive application.

An additional benefit with the refurbishment option is that, with the properties of Plasmet T, the life of the roller will now be greater than that of a new roller – adding to the cost benefits of using Corrocoat coating systems

view the details

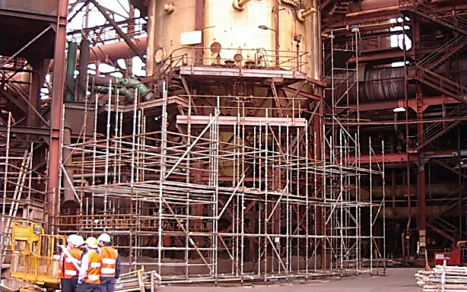

Prior to Corrocoat Engineering Victoria’s involvement in 1995, this critical pressure vessel required patch weld repairs every six months,

necessitating regular scrubber shutdown periods to combat corrosion which was causing through-plate perforation and leaking.

Corrocoat Engineering Victoria first treated the vessel in 1995,

and subsequent inspections have shown these original areas of repair to be intact and corrosionfree.

Repairs carried out between 1995 and 2003 have now resulted in the coating of the entire internals of the pressure vessel – a total in excess of 200m2. Without

Corrocoat protection, it would by now have been necessary to replace the entire base of the blast furnace venturi scrubber.

view the details