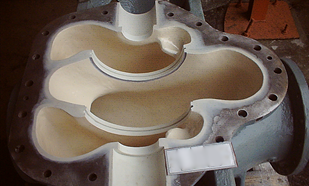

Refurbish from scrap. A complete Package for Pump Service, Repair and Protection. Severe corrosion/erosion dam …

The pumps are an important asset in the Industry. Since its founding, Corrocoat Japan has been working in pump repair for diverse industries.

Based on that experience and achievements, we have established a unique technology that combines corrosion engineering and mechanical engineering to help our clients with the maintenance cost.

Corrocoat Japan contributes to the industry by providing long-term protection of plant equipment through its unique pump coating system and excellent pump engineering.

This is really that pump !?

These are the words we often receive from our customers.

Pump servicing

Pump repair & refurbishment

Lifespan extension

Engineering Excellence. After 27 years of corrosion coating application, this pump still running in good condi …

Pump engineering

Comprehensive pump maintenance

Normal maintenance does not end. A complete commitment with the client is Corrocoat pump maintenance. Since it …

Re-manufacture, modification, coating application

The highest added value for coated and refurbished equipment. Manufacturing, engineering, and modification of …

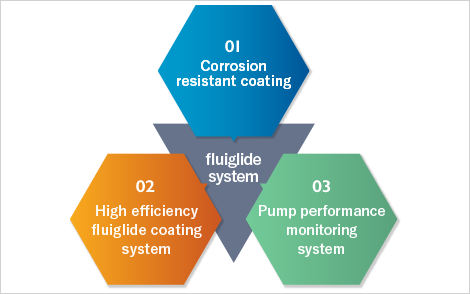

Pump energy saving and Monitoring

Pump energy saving fluiglide and monitoring

Pump performance improvement efficiency improvement and pump monitoring system Improving pump performance and …

Fluiglide friction-reducing energy, efficient protective coating system

Corrosion resistant coating. “Benefits” Corrosion resistant protection. Repair and refurbishment W …

〔 A complete package for Pump Service, Repair and Protection 〕

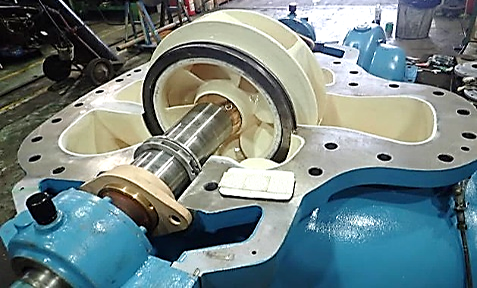

- Providing excellent long-term performance, we combine mechanical engineering with advanced polymer technology allowing even severely damaged pumps to be refurbished at a fraction of the replacement cost, often without expensive replacement parts.

- All pumps & pump parts are repaired with upgrades in materials and tightening of tolerances to improve pump life, efficiency, and performance.

- Pumps are protected against corrosion using Corrocoat's tried and tested coatings - the selection of which is dependent on the service environment.

- Every refurbished pump is returned to the customer with its own 'Completion Pack' giving assurance to the client that the work has been carried out to the highest standard.

- The Completion Pack contains performance test data, an internal hydrostatic test certificate, and details of all work carried out with relevant photographs are also included.

〔 Pump Engineering 〕

Comprehensive service for repair, refurbishment, and protection, including specialist procedures for:-

- Severe corrosion/erosion damage in areas such as volutes, cutwaters, and neck rings

- Reprofiling of water passages

- Coating machined areas such as neck ring joints

- Returning coated components to original tolerances, facilitating the return of good pumping efficiency

- Sophisticated mechanical engineering capabilities including the shafts remanufacture.

- Metal stitching and laminating techniques. We respond to individual requirements to provide equipment quickly and to budget for the all-around service we offer.

- Site removal and transportation

- Replacement of components

- Refurbishment of mechanical seals

- Shaft reclamation and in-house dynamic balancing of rotating components