Can be used in a wide variety of areas

Completely repair thin and corrosion-damaged parts

with 70 types of coating and fiberglass materials.

Corrocoat’s products and techniques have been used extensively for projects ranging from corrosion protection for new-build steelwork to turnkey bridge restoration schemes, bringing together coating and engineering skills.We have a wide variety of internal lining materials for various corrosive environments as well as high-temperature areas.

Unlike general purpose epoxy coating materials, Corrocoat’s epoxy coating system not only offers excellent costeffectiveness but also provides added value such as high corrosion resistance and an environmentally friendly surface treatment.

Refining Industry. Electric dust collector repair and lifespan extension.

Coating applications are adopted to prolong the useful life of the equipment that corrodes due to aging.

Damaged and thinned parts coated.

In the repairs, fiberglass is used in combination with the coating material “Plasmet ZF / ZX, Epoxy Resin”

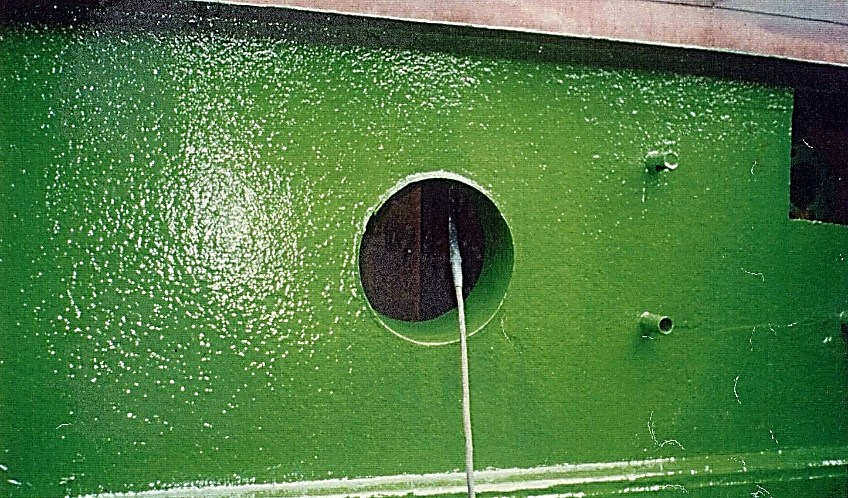

Power and Gas Industry. Flood diversion steel structure (sheet pile support). Protection against saline environments.

The project changed from structure renovation to coating application due to low cost and other advantages.

Originally, this project was to restore the old sheet pile support, but due to cost, the client decided to extend the life rather than replace it.

Corrocoat’s “Plazmet ZF” and “Corosen AP1” are used to extend the life of the sheet pile support.

Plazmet ZF has improved rust prevention and corrosion resistance, and “Corosen AP1” has improved “color retention” and “aesthetic maintenance” due to weather resistance.

One Point

Saline environments protection for marine steel structures such as bridges, piers, and caissons is done outdoors with a wide range of coating products for highly corroded areas such as splash zones and tide zones.

By using a highly corrosion-resistant coating material that can suppress oxidation and passivate, long-term corrosion protection is possible at the lowest cost.