| Project | 230℃ Sludge combustion gas line corrosion protection |

|---|---|

| Target | Cost reduction maintenace by coating application |

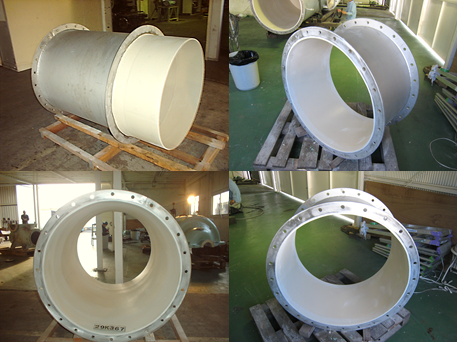

Photo description

After completion of 230℃ gas line coating (new items)

After completion of 65℃ gas line coating (existing items)

Sludge combustion equipment *Numbered parts are coated parts

Customers and industries

Chemical Industry

Target equipment

Sludge combustion equipment

Target Item

Exhaust gas piping, blower casing, chimney

Coating period

Continus from 2009

Scope of work

Sludge combustion exhaust gas line

Materials used

■ Within 185℃: Polyglass VE, VEF, Coroglass 600

■ Within 260℃: Corrothasne XT

■ Within 260℃: Corrothasne XT

Coating process

■ Existing items: Surface preparation, cleaning treatment, corrosion-resistant coating application.

Venture / thinning part: Glass fiber laminating treatment

■ New Items: Surface preparation, cleaning treatment, corrosion resistant coating application.

Venture / thinning part: Glass fiber laminating treatment

■ New Items: Surface preparation, cleaning treatment, corrosion resistant coating application.

Merits of this application

■ The use of special metals for corrosion also presents thinning of walls and holes due to the advance of corrosion.

■ Corrosion progresses throughout the plant due to exhaust gases containing filtered sulfur.

■ The Corrocoat products used in this application have shown great efficiency in saving maintenance costs.

■ Corrosion progresses throughout the plant due to exhaust gases containing filtered sulfur.

■ The Corrocoat products used in this application have shown great efficiency in saving maintenance costs.

Corrocoat Japan credentials etc

■ Even now, 12 years after applying the coating, the strength is maintained and is adopted as a permanent measure.

■ Based on performance evaluation, the linning application is still being adopted.

■ Especially, the coating work on the 230℃ lines is highly recognized by the customer.

■ Based on performance evaluation, the linning application is still being adopted.

■ Especially, the coating work on the 230℃ lines is highly recognized by the customer.