| Project | Life span extension of a chlorine gas |

|---|---|

| Target | High temperature & corrosion piping inner surface corrosion |

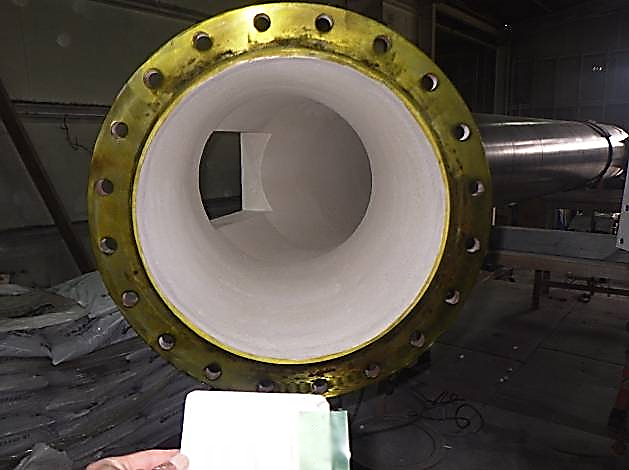

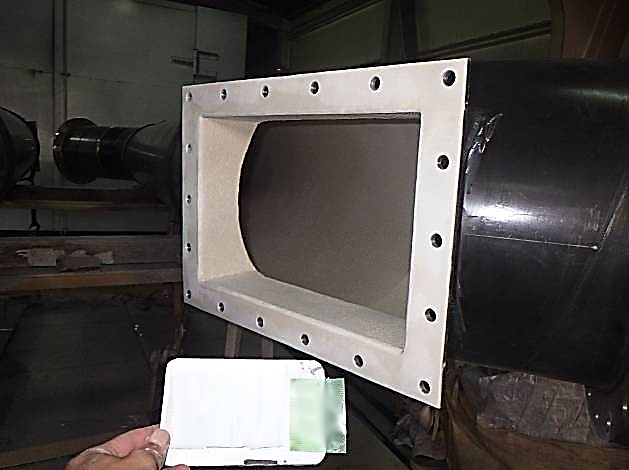

Photo description

Inner coating completed

Inspection of flange surface after coating is completed

Before coating

Customers and industries

Chemical Industry

Target equipment

200℃ hydrochloric acid gas (hydrogen chloride) piping

Target Item

Φ500 × L5600 2 new pipes

Coating period

October 2019

Scope of work

Pipes inner surface, inspection and flange surface forming

Materials used

Corrothane XT

Coating process

■ Grit blast to Sa2-1 / 2 (equivalent to SSPC SP10)

■ Coating the edge surface

■ Coating: Spray & hand coat

■ Fitting surface

■ Completion inspection: film thickness, pinhole and visual inspection

■ Coating the edge surface

■ Coating: Spray & hand coat

■ Fitting surface

■ Completion inspection: film thickness, pinhole and visual inspection

Merits of this application

■ Adopted after the good results of the test piece in a high temperature and high corrosion environment.

■ Operating temperature of this pipe is 200°C, and since it has a chlorine gas, a coating material with excellent heat resistance and chemical resistance is required.

■ Features of Corrothane XT

・ According to product specifications, it has a heat resistance of 160℃ in a liquid environment and 260℃ in gas environment.

・ It can be used at full pH (pH 0-14).

・ It has been widely adopted as a countermeasure in high temperature and high corrosion environments.

■ Coating measures were established in a highly corroded environment.

■ Measures by coating in a highly corroded environment have become standard.

■ Operating temperature of this pipe is 200°C, and since it has a chlorine gas, a coating material with excellent heat resistance and chemical resistance is required.

■ Features of Corrothane XT

・ According to product specifications, it has a heat resistance of 160℃ in a liquid environment and 260℃ in gas environment.

・ It can be used at full pH (pH 0-14).

・ It has been widely adopted as a countermeasure in high temperature and high corrosion environments.

■ Coating measures were established in a highly corroded environment.

■ Measures by coating in a highly corroded environment have become standard.

Corrocoat Japan credentials etc

■ Corrocoat coating in a highly corroded environment has become established.