| Project | Nickel refining pilot plant corrosion resistant coating trial |

|---|---|

| Target | Corrosion resistant coating on the inner surface of the tank |

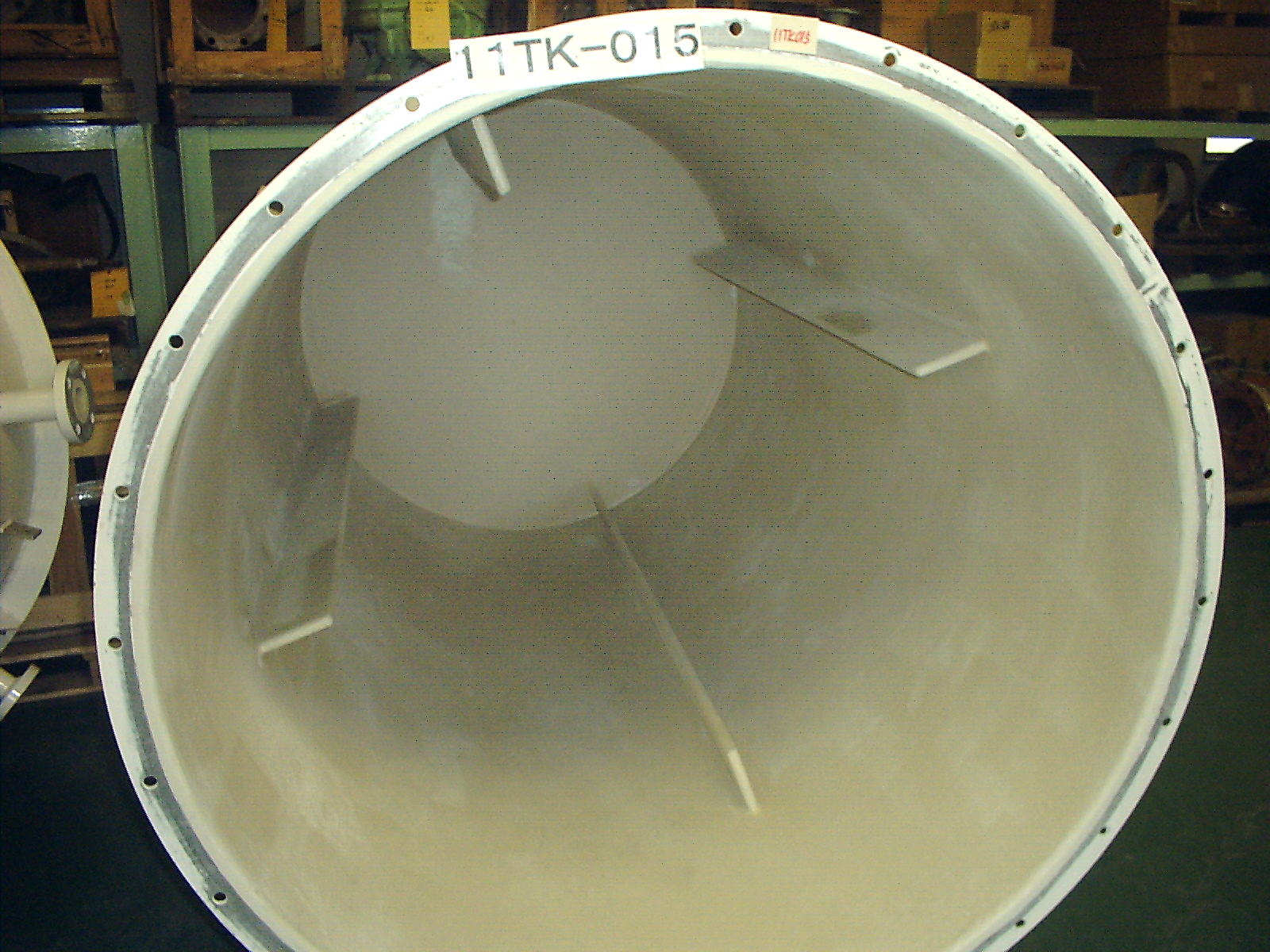

Photo description

Before application-new tank

Inner surface coating completed-corner / welded glass fiber laminating process

Manhole cover coating completed

Customers and industries

Minning

Target equipment

Nickel refining equipment

Target Item

Pilot plant tank

Operating temperature: 60°C

Operating temperature: 60°C

Coating period

March 2009

Scope of work

Tank inner surface coating construction, including attached parts: Top cover, manhole cover.

Materials used

Polyglass VEF, Polyglass VE, Coroglass 600 laminating resin for glass fiber laminating

Corrothane XT

Corrothane XT

Coating process

Spray & hand coating

Merits of this application

■ This product can be used in the pH range of 0-14.

■ Covers up to 110℃ in liquid and 185℃ in air.

■ Can be installed in a short time by spraying application.

■ Even with respect to expansion, contraction, and deflection, which are a concern in large tanks, the coating rate of elongation and thin-film construction provide enough flexibility.

■ Standardization of reinforcement works for tank corners and weld by fiberglass lamination treatment

■ Construction on the flange surface of the nozzle connection

■ Covers up to 110℃ in liquid and 185℃ in air.

■ Can be installed in a short time by spraying application.

■ Even with respect to expansion, contraction, and deflection, which are a concern in large tanks, the coating rate of elongation and thin-film construction provide enough flexibility.

■ Standardization of reinforcement works for tank corners and weld by fiberglass lamination treatment

■ Construction on the flange surface of the nozzle connection

Corrocoat Japan credentials etc

■ Recognition of superiority of coating application in a chemical environment

■ Application in a similar environment

■ Application in a similar environment