From tanks, pipes, and steelwork to concrete, Corrocoat products enable long-term corrosion protection in a variety of environments and applications.

On-site construction, efficient spraying for wide areas and different application methods for high temperature and corrosive areas such as flues, high conductivity/high chemical concentration environments, seawater related equipment.

View Plant protection

With the high engineering skills provided by the Corrocoat coating system, we can expand the life span of capital assets by applying corrosion-resistant coatings.

The wide range of coatings makes it possible to apply our products in different operating conditions and environments.

View Equipment repair

We provide added value through the innovative features of our coating materials.

Plasmet ZF, has rust conversion/suppression features and high anti-corrosion performance.

Our products can achieve in a short time low-cost total corrosion protection.

Biofoul is a heavy-duty,anti-foul coating developed to provide optimum protection in both seawater and freshwater environments where biofouling and marine growth are evident.

View Special application

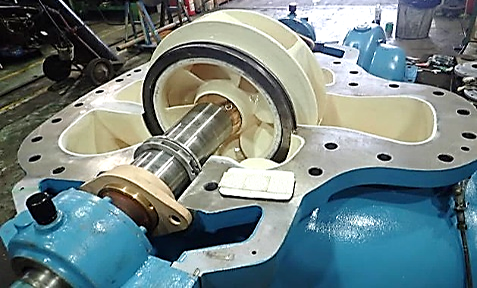

The know-how of corrosion resistance technology and pump engineering developed through time has resulted in Corrocoat’s unique pump coating system.

Our lining material with excellent wear and corrosion resistance and our unique repair technology not only enables the repair, regeneration, and functional recovery of various severely damaged pumps, but also achieves long-term protection.

View Pump repair & refurbishment

Corrocoat’s engineering department responds to a wide range of customer needs in pump maintenance operations.

In addition to pump maintenance, we also consider lining and the use innovative technology for repairs planned for long-term operation. We handle part manufacturing, part upgrading, and in-house machining.

View Pump engineering

With the Pump Energy Saving Fluiglide system, we achieve high pump efficiency and energy savings through pump corrosion resistance protection/repair coatings and original measuring technology of pump performance.

The fluiglide system allows significant energy savings and contributes to the reduction of CO2.

View Fluiglide energy saving coating system