Pump performance improvement

efficiency improvement and

pump monitoring system

Improving pump performance and pump efficiency has been a priority in pumping systems.

Although pumps have an important role in the industry, there are few ways to improve pump efficiency only, by mechanical refurbishment great results cannot be expected.

The fluiglide energy-saving coating system is a special anti-corrosion product that recovers the original efficiency of the pump with great savings in electrical energy and contributes to the reduction of CO2.

The pump performance monitoring service allows a precise understanding of the current performance of the pump and, based on the analysis of the data obtained by the measurement, the energy savings after the fluiglide coating system application can be verified.

CHECK

Our services allow us to quantify the rate of energy savings prior to the application of the fluiglide system.

The actual rate of energy savings depends on the type of pump and operating conditions, but many products achieve more than 8% and, in some cases, can exceed 10%.

The Pump energy saving fluiglide system includes:

Before application

After application

- Pump repair, refurbishment and extend the lifespan

- Improve pump performance and efficiency

- Recovery / optimization of pump performance

- Saving electric power consumption

- Reduction of operating pumps in operation in a pumping system

- High efficiency long-term maintenance

- Save maintenance costs

- Pump performance measurement / monitoring

Corrocoat Japan handles everything from analizing if a pump can improve performance and efficiency (pump orientation support), measuring pump performance, saving energy with fluiglide coating, and measuring results after construction.

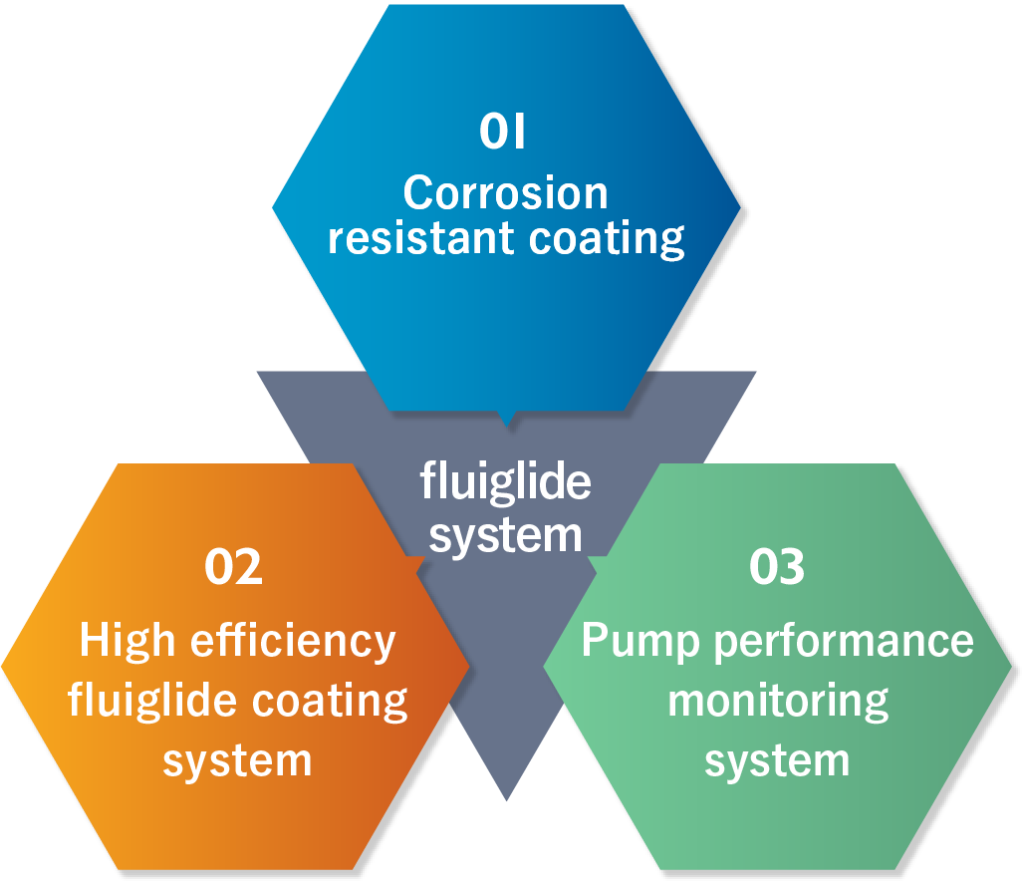

What is a pump energy saving fluiglide system?

The fluiglide anti-corrosion system aims to save energy consumption in the pump by incorporating the “three elements” that have the maximum effect in improving the performance and pump efficiency. This is an exclusive system of Corrocoat.

Three elemts of the

fluiglide system

Pump energy saving fluiglide system

- Corrosion resistant coating

- High efficiency save energy coating

- Pump performance monitoring system

The concatenation of these three elements, allows all the functions of “corrosion protection”, “repair and refurbishment”, “energy saving”, “redesign”, “performance measurement” and “operation improvement”.

Click here for details on the

three elements

Case study

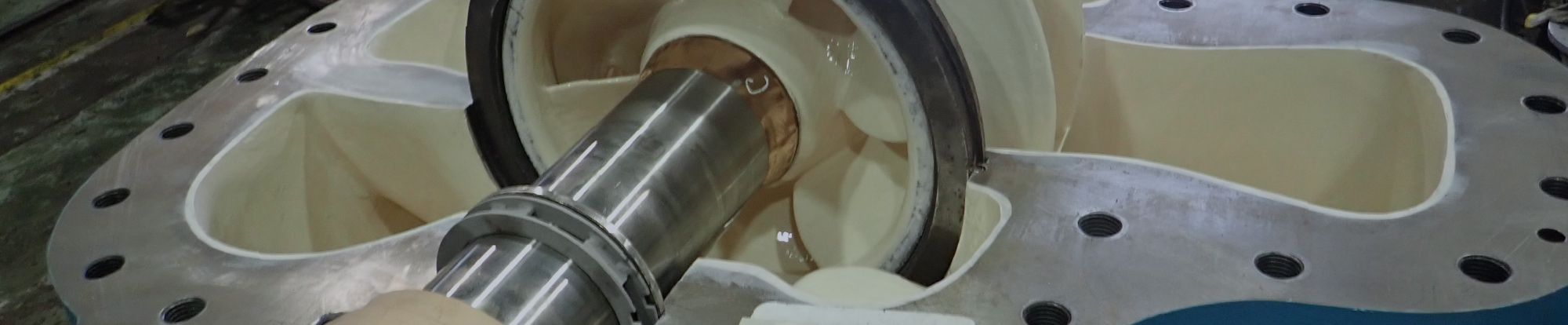

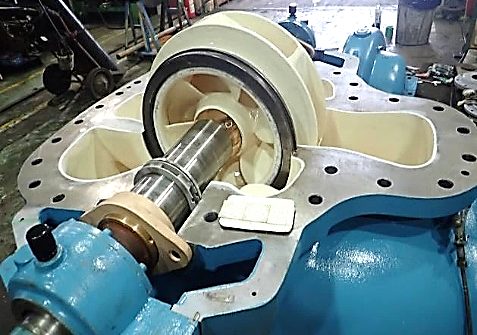

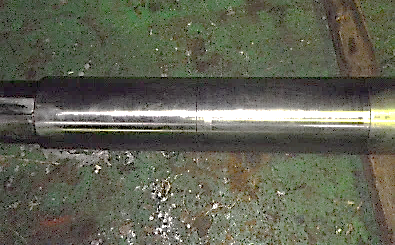

Chemical Industry: Φ500 × 350 Double suction cooling tower pump 400㎾

DATA

| Power saving | :9.2% 35.36kW/h |

| Coating target | :Upper and lower casing, impeller |

| Construction range | :Pump performance measurement (before and after construction), fluiglide coating construction, disassembly and maintenance |

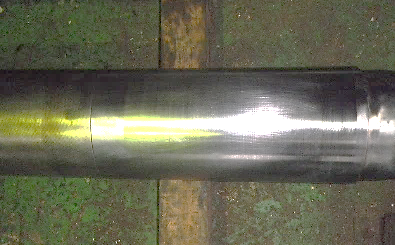

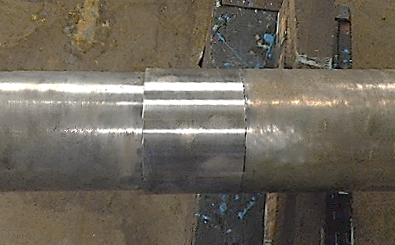

After the fluiglide coating

Parts manufactured

Assembly

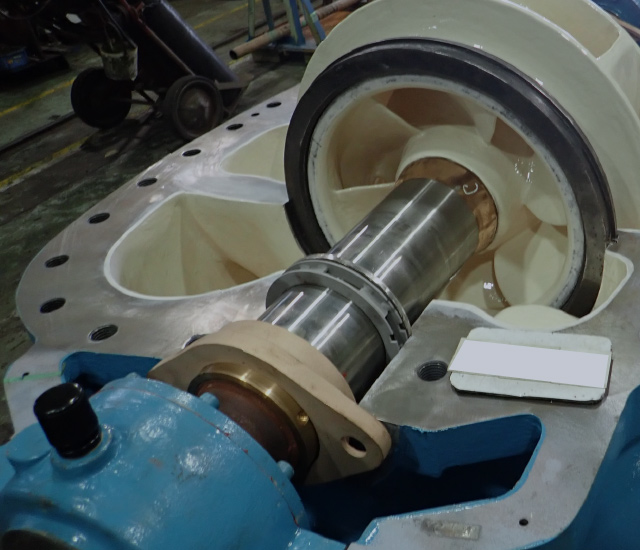

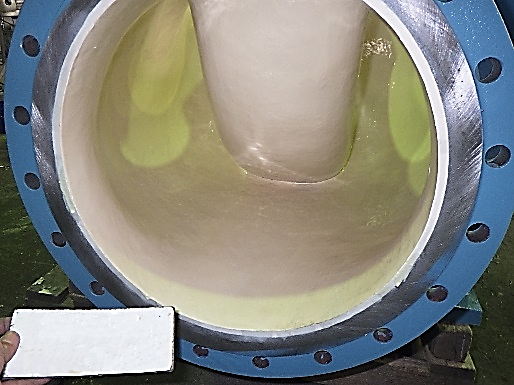

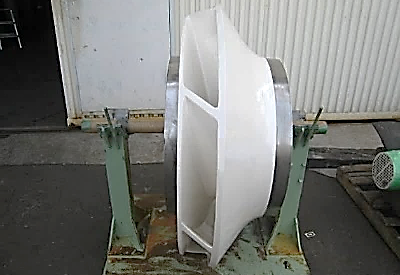

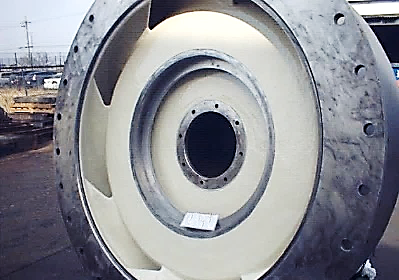

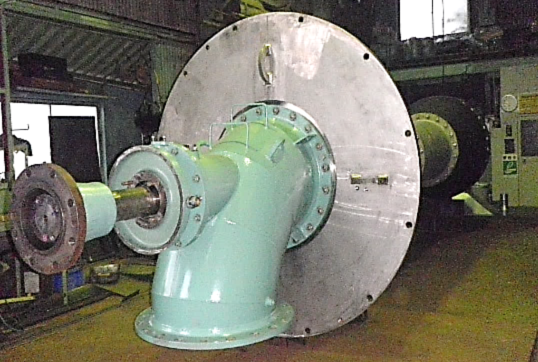

Chemical Industry: Φ800 vertical cooling water pump

DATA

| Coating target | :Bell suction, impeller, casing |

| Coating material used | :Coroglass, Fluiglide |

After the fluiglide coating is completed

Parts manufacturing and installation

After assembling

One Point

Corrocoat Japan’s original high-precision pump reconditioning system reliably improves the performance and efficiency of pumps that have been used for a long time.

Click here for details on the

three elements