| Project | PLASMET T FOR SLUDGE ROLLERS |

|---|---|

| Target | WEAR RESISTANCE FOR EFFLUENT SLUDGE ROLLERS |

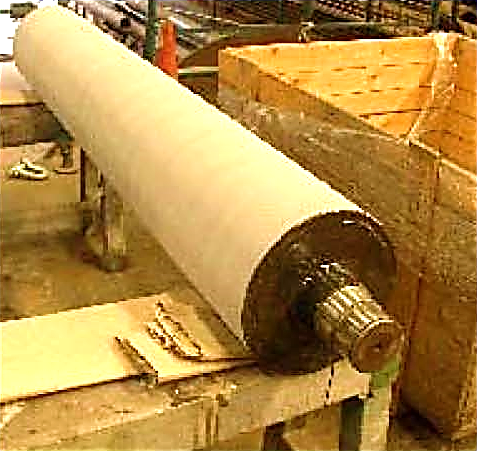

Photo description

Rollers on arrival into our works.

The roller is pre-machined, and grit blastedblasted before the application process begins.

The post machined roller ready for packing and despatch.

Customers and industries

Water and Waste industry, UK.

Target equipment

Waste equipment

Target Item

Sludge rollers

Coating period

September 2004

Scope of work

Rebuilding and protecting severely worn sludge rollers to original dimensions.

Materials used

Plasmet T

Glass fibre reinforcing

Glass fibre reinforcing

Coating process

get back to good

・ Grit blasted to ISO 8501-1 cleanliness standard Sa2.

・ Plasmet T applied with 100mm wide glass fabric reinforcement.

・ Post machine to final drum sizes.

・ Grit blasted to ISO 8501-1 cleanliness standard Sa2.

・ Plasmet T applied with 100mm wide glass fabric reinforcement.

・ Post machine to final drum sizes.

Merits of this application

Plasmet T is a highly abrasion resistant coating when used on it’s own, and when coupled with glass fibre reinforcing, as in this application, builds strength and thickness to these worn sludge rollers.

Plasmet T is a machinable coating designed to achieve a smooth surface finish.

This high specification system ensures the long life of the rollers in this highly abrasive application.

An additional benefit with the refurbishment option is that, with the properties of Plasmet T, the life of the roller will now be greater than that of a new roller – adding to the cost benefits of using Corrocoat coating systems

Plasmet T is a machinable coating designed to achieve a smooth surface finish.

This high specification system ensures the long life of the rollers in this highly abrasive application.

An additional benefit with the refurbishment option is that, with the properties of Plasmet T, the life of the roller will now be greater than that of a new roller – adding to the cost benefits of using Corrocoat coating systems

Corrocoat Japan credentials etc

Using coating as a method of refurbishment has proved cost and time effective.

Traditional methods of welding and machining have a turn around time of weeks, and replacement is expensive. Corrocoat’s solution can be turned around in days and is around half the coat of a new roller.

Traditional methods of welding and machining have a turn around time of weeks, and replacement is expensive. Corrocoat’s solution can be turned around in days and is around half the coat of a new roller.