We are able to meet the demands

of all pipe shapes

Coating material & application method

for pipe work

Corrocoat materials were developed specifically for application to pipe internals and externals used in even the most arduous conditions. We provide established solutions, offering protection for new lengths of pipe during installation as well as refurbishment options for preexisting pipework.

We specialize in both internal linings and external coatings and we utilize a range of specialist application techniques offering high-quality finishes combined with fast turnaround and reduced downtime.

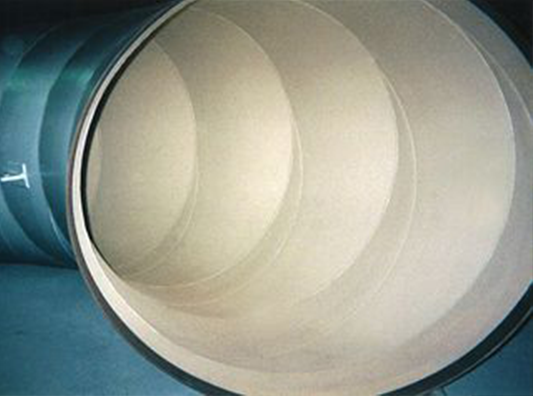

Chemical Indutry: Φ500 pipe of avertical cooling water pump

Spray application: Φ500 or more, straight pipe / curved pipe, whichever the case is not a limitation.

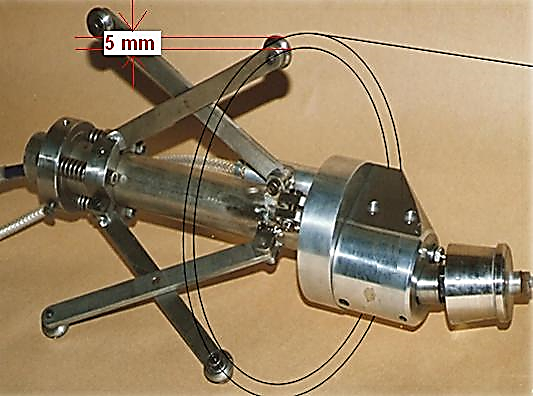

IN-SITU PIPE COATING – WINCHED SYSTEM

The coating is spray applied, being atomized by centrifugal force produced by the specially developed spray cup. A fan spray pattern is produced by the unique multi-axial head, providing a precise, consistent and rifle mark free finish at a variety of predetermined thicknesses.

From Φ100 to Φ700.

PIPE SPINNING / ROLLING RIG

Pipe spinning is used to internally coat straight lengths of pipe from 80 mm to 600 mm diameters.

Pipe lengths of up to 18 meters can be accommodated.

FLOOD & DRAIN (POURING)

For small diameter pipes, difficult orientations, limited by the ability to lift and handle the pipes. By pouring a coating material on the pipe, it is possible to coat not only thin pipes but also curved pipes by turning them manually.

HAND COATING

Even small small pipes can be manually coated by skilled staff.

One Point

Our wide range of pipeline products is suitable for high-temperature environments up to 260°C, sewage, chemicals and seawater where severe corrosive and wear environments are present.