| Project | Multi-stage pump maintenance |

|---|---|

| Target | Pump maintenance, parts manufacturing, repair & lifespan extension |

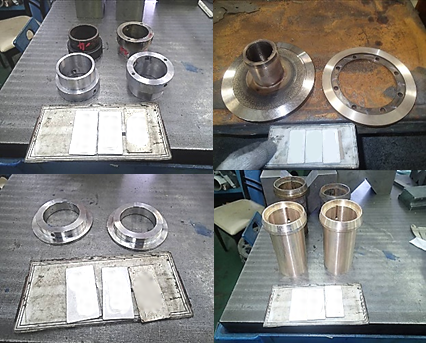

Photo description

After maintenance and repair completed

Parts manufactured

Impeller and casing coating

Customers and industries

Steel Industry

Target equipment

Multi-stage pump

Target Item

Horozontal axis 4-stage pump

Coating period

July 2017

Scope of work

All construction except thermal spraying is done at CCJ

■ Disassembly and maintenance

・ Additionally to disassembly, assembly, and rigorous inspections, parts manufacturing and refurbished.

・ Coating application to deteriorated parts to extend the lifespan.

・ Coating application within the required construction period.

■ Disassembly and maintenance

・ Additionally to disassembly, assembly, and rigorous inspections, parts manufacturing and refurbished.

・ Coating application to deteriorated parts to extend the lifespan.

・ Coating application within the required construction period.

Materials used

■ Molding / Abrasion resistance: Plasmet R, Plasmet T

■ Corrosion resistance: Plasmet ZF, Plasmet ZX

■ Repair and refurbish: Polyglass VE

■ Corrosion resistance: Plasmet ZF, Plasmet ZX

■ Repair and refurbish: Polyglass VE

Coating process

■ Acceptance inspection

■ Pump disassembly / assembly / adjustment

■ Repair of each part (coating, thermal spraying)

■ Parts manufacturing and replacement of consumable parts

■ Various inspections (coating film thickness/appearance, impeller dynamic balance)

■ Reporting documentation with photo files for each process

■ Pickup and delivery

■ Pump disassembly / assembly / adjustment

■ Repair of each part (coating, thermal spraying)

■ Parts manufacturing and replacement of consumable parts

■ Various inspections (coating film thickness/appearance, impeller dynamic balance)

■ Reporting documentation with photo files for each process

■ Pickup and delivery

Merits of this application

■ We are not only limited to disassembly and maintenance, but we can provide total support such as parts manufacturing and repair by coating.

■ Add value such as repair and regeneration and extension of life can be obtained.

■ Respond within the required construction period.

■ Coating is selected according to environment and application such as corrosion resistance, wear resistance, and molding.

■ Add value such as repair and regeneration and extension of life can be obtained.

■ Respond within the required construction period.

■ Coating is selected according to environment and application such as corrosion resistance, wear resistance, and molding.

Corrocoat Japan credentials etc

■ Demonstrate the added value of extending equipment lifespan through Corrocoat coatings.

■ Establish reliability for one-stop service by supporting total construction, including parts manufacturing.

■ Establish reliability for one-stop service by supporting total construction, including parts manufacturing.