Dealing with corrosion requires high costs and a long repair period, which has become a big problem for enterprises.

Corocoat’s coating materials and construction methods enable long-term plant protection as well as repair, even in harsh conditions where construction in hightemperature, high-corrosion environments has been difficult.

View High temperature and corrosion

Long-term maintenance in chemical and seawater environments is a major problem that many industries cannot avoid and often requires a lot of resources to solve corrosion problems.

Corrocoat enables long-term plant maintenance with unique engineered, highly corrosion-resistant coating materials, even in harsh environments.

Power companies operating in a variety of chemical environments, as well as petroleum refining industry, and seawater treatment plants find many distinctive, corrosion-resistant applications from our products.

View Chemicals and seawater

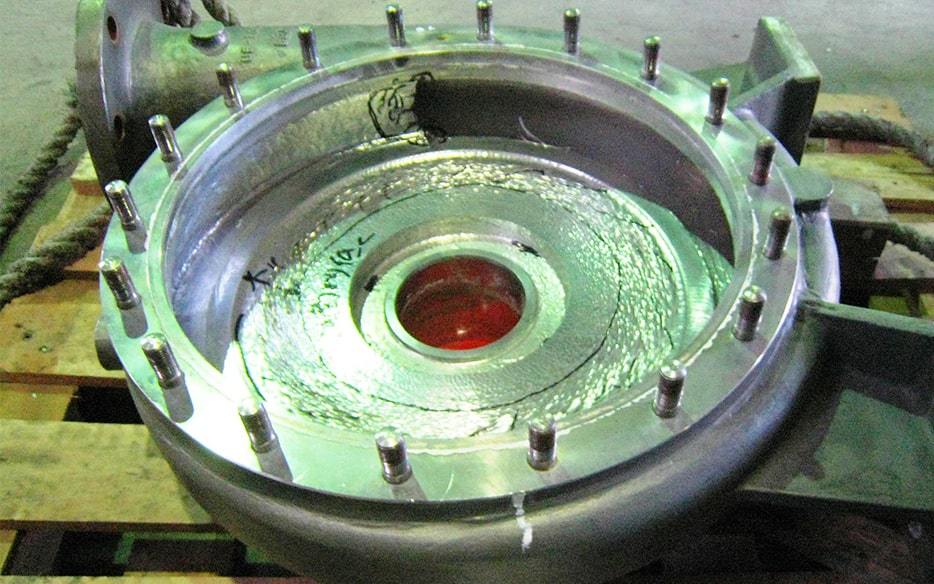

The repair of wear-related equipment such as scales in steel companies and coal ash in power plants has been considered endless activity.

Corrocoat has many applications using coating materials that specialize in wear resistance that not only repair and rebuild equipment but also extend the lifespan.

The wear and chemical resistance of our coatings, combined with different surface treatments and precise metal repairs, make it possible to carry out value-added repairs considering the diverse operating conditions.

View Wear environment

Corrocoat’s extensive experience is also applied in the field of freshwater, and in domestic public works, as well as the industrial water and industrial wastewater, the wide specification range (in liquid: pH 0 to 14, maximum 160 °C) of the Corrocoat coating material that allows solving many problems of corrosion.

The Corrocoat coating materials allow for long-term protection and provide safety and security.

View Water, sewerage & wastewater