| Project | Drainage plant discharge flap valve. Antifouling coating |

|---|---|

| Target | Corrosion resistance, frame repair, and antifouling coating of large flap valves. |

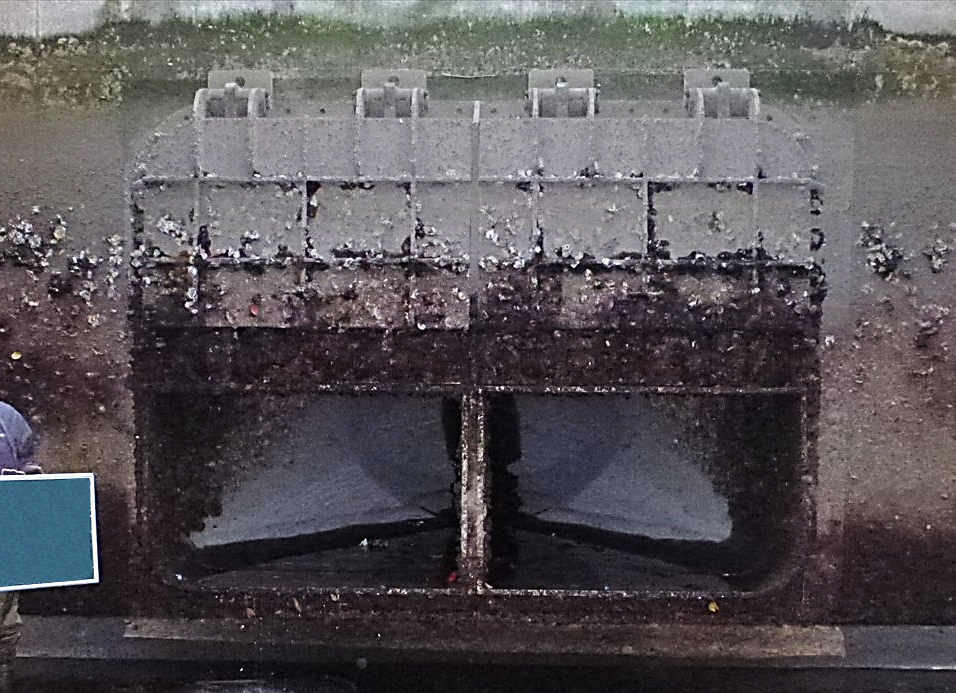

Photo description

Before coating, presence of marine growth.

After the antifouling coating, Biofoul is completed.

20 months after application. No marine growth was presented.

Customers and industries

Public facilities

Target equipment

Drainage pump station (River estuary area drainage plant)

Target Item

Flap valve

Coating period

01 February 2014

Scope of work

Because of remarkable corrosion progression in the discharge side flap valve of the drainage plant at the river estuary area, the plant pump system was facing serious operating problems. The Client was looking for long-term corrosion protection to provide optimum protection in both sea and freshwater environments and solve the related problems with continuous maintenance.

Materials used

■ Base coat: ZIPCOAT (corrosion resistance)

■ Top coat: Biofoul (prevents marine growth)

■ Top coat: Biofoul (prevents marine growth)

Coating process

■ Before construction: sever corrosion

■ Desalinization washing

■ Blast to SIS Sa 2.5 (equivalent to SSPC SP 10)

■ ZIP Coat, spray application (> 800μm)

■ Biofoul spray application ( > 250μm)

■ Desalinization washing

■ Blast to SIS Sa 2.5 (equivalent to SSPC SP 10)

■ ZIP Coat, spray application (> 800μm)

■ Biofoul spray application ( > 250μm)

Merits of this application

■ Environment: River estuary area

■ Avoid corrosion progress of flap valves and prevent marine growth. Although the butterfly valve is made of stainless steel, the progress of corrosion becomes evident due to the influence of deposits.

Prevent leakage from the flap valve seals.

■ Avoid corrosion progress of flap valves and prevent marine growth. Although the butterfly valve is made of stainless steel, the progress of corrosion becomes evident due to the influence of deposits.

Prevent leakage from the flap valve seals.

Corrocoat Japan credentials etc

In December 2013 after periodic maintenance of a drainage vertical pump, the discharge pipe side and the valve body lost the sealing function due to adhesion of marine growth and corrosion.

After coating application, In addition to the protection against marine growth, the efficiency of the pump increased due to the improvement in suction.

After coating application, In addition to the protection against marine growth, the efficiency of the pump increased due to the improvement in suction.