| Project | WATER JET PUMPS OF HIGH-SPEED FERRY EROSION REPAIR - FUEL SAVINGS |

|---|---|

| Target | Corrosion / wear resistance repair & fuel efficiency improvement |

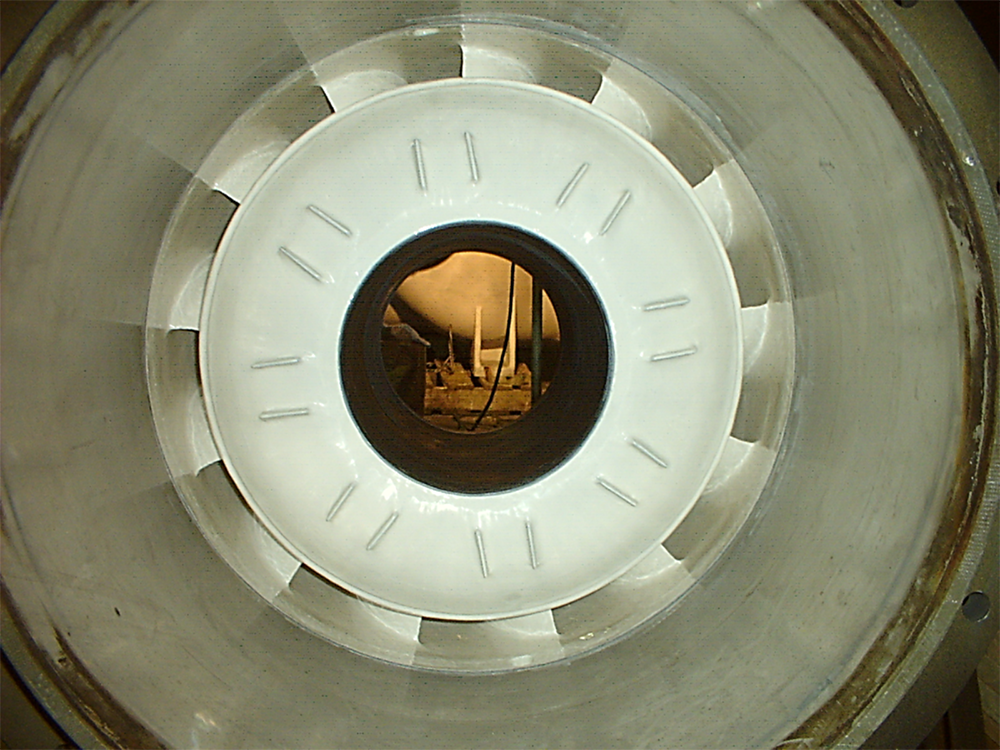

Photo description

Elimination of the damaged part of the dome.

Installation of the newly manufactured dome.

Corrosion-resistant and energy-saving coating application completed.

Customers and industries

Marine

Target equipment

Jetfoil

Target Item

Water jet pump stator housing

Coating period

From 2000- Annual coating maintenance

Scope of work

Protection against seawater corrosion, erosion, and cavitation, besides recovery the performance of Waterjet pumps through coating repair of the dome, guide vanes, and wet area.

Jetfoils include as part of their maintenance program the coating of their Waterjet pumps.

Jetfoils include as part of their maintenance program the coating of their Waterjet pumps.

Materials used

■ Corrosion resistance: Corroglass 200

■ Energy saving: Fluiglide

■ Energy saving: Fluiglide

Coating process

■ Grit blast to Sa2.5 for repair areas

■ Repair with Corroglass 200 & 600

■ Check of minimum design tolerances in critical areas.

■ Fluiglide aplication

■ Repair with Corroglass 200 & 600

■ Check of minimum design tolerances in critical areas.

■ Fluiglide aplication

Merits of this application

■ Conventionally, after prolonged use, the WJP is replaced with a new one due to damage progress.

■ When the Jetfoil cruises at 43knots FOILBORNE speed, the gas turbine fuel (gas oil) consumption rate is approximately 2,150 l/h, after the Fluiglide the application, the savings run between 5 to 7% of fuel consumption this represents up to 150 lt/h in savings.

■ When the Jetfoil cruises at 43knots FOILBORNE speed, the gas turbine fuel (gas oil) consumption rate is approximately 2,150 l/h, after the Fluiglide the application, the savings run between 5 to 7% of fuel consumption this represents up to 150 lt/h in savings.

Corrocoat Japan credentials etc

■ As a result, repair costs and fuel consumption can be reduced by using a fluiglide coating.

■ Repair costs are quickly recovered from savings in fuel consumption.

■ Due to the excellent results Corrocoat products have shown in protecting against erosion and reducing fuel consumption of Waterjet pumps, 7 companies have incorporated the fluiglide coating system as part of their preventive maintenance services.

■ Repair costs are quickly recovered from savings in fuel consumption.

■ Due to the excellent results Corrocoat products have shown in protecting against erosion and reducing fuel consumption of Waterjet pumps, 7 companies have incorporated the fluiglide coating system as part of their preventive maintenance services.