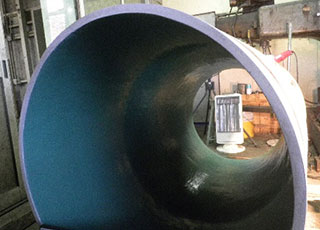

Whether it’s protection for new or existing plants, our coating solutions are the fast, convenient and economical answer. In our workshops or on-site, either way, our high-quality coatings provide equipment with a new lifespan.

Outline of

Coating Application

“STANDARD PROCESS”

Equipment arrival

Visual Inspection

Define the optimum service plan

The engineering department verifies the item conditions to determine the optimum service plan, and guides the customer under coordination with the sales department every time the process changes

Masking areas for protection from grit blasting

First blasting process

Elimination of rust and dirt from the surface to check the deterioration state of the target item.

The specialized blasting team proceeds with the grit blasting, cleaning, and drying of all components. The quality of this procedure is basic for the correct application of the coating system. Corrocoat’s blasting team has set strict acceptance standards, and servicing cannot continue until the standards are met.

After cleaning and drying

Second grit blast

Coating application

Molding process, machining parts and other repairs.

Coating inspection

Thickness test, pinhole test, etc.

Top coat aplication

Finishing coating application

Heat treatment

Assembly completion / completion inspection

Shipping

Process is standard and planned according to the condition and geometry of the item, place of operation, etc.