Standard service to repair, regenerate, increase lifespan, and functional recovery of pumps with the anti-corrosion coating system.

01

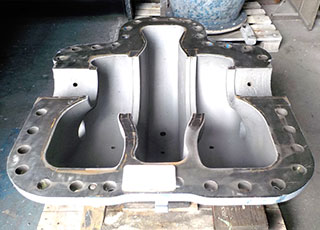

“Before service”

PRE-REPAIR PROCESS

Pump arrival

Visual inspection / Service confirmation

Checklist before service.

Disassembly

Visual inspection and part sizing.

Comprehensive pre-service inspection.

The specialized blasting team proceeds with the grit blasting, cleaning, and drying of all components. The quality of this procedure is basic for the correct application of the anticorrosive coating system. Corrocoat’s blasting team has set strict acceptance standards, and servicing cannot continue until the standards are met.

02

“Service planning / proposal”

REPAIR PLANNING / PROPOSAL

Define the optimum service plan

The engineering department verifies the item conditions after disassembly, inspection, and primary grit blasting to determine the optimum service plan, and guides the customer under coordination with the sales department.

03

“Repair &maintenance service”

REPAIR / MAINTENANCE CONSTRUCTION PROCESS

Masking areas for delete protection from grit blasting

First grit blasting

Cleaning/washing blasted items

Second grit blasting

All grit blasting protection tape is removed before the coating is applied.

Coating application

Parts manufacturing/molding and profile adjustment / various other repairs.

Quality inspection

Top coating

Finishing process

Parts manufacturing and repair

Manufacture and replacement of damaged parts.

Assembly process

Verification of parts dimensions and fittings.

Coating completion inspection

Assembly completed

Shipping

This is a standard process and is planned according to the condition

and shape of the pump, the place of operation, etc.